Through determined innovation, Prevex successfully raised the amount of recycled polypropylene (rPP) in its water traps to 55 percent in 2023. However, the company has continued to develop new solutions to reach an even higher percentage.

In May 2024, a big milestone was achieved when Prevex’s newest investment, an extruder, was put into operation at the company’s Nykarleby factory.

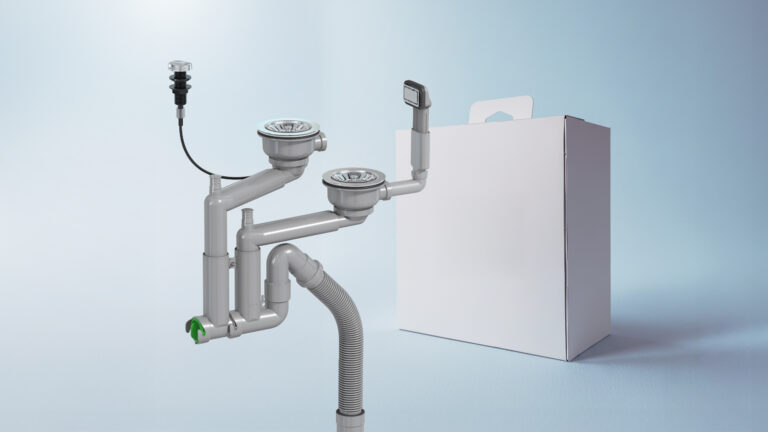

“With this machine, we manufacture flexible outlet pipes made of 51 percent recycled plastic for our bathroom water traps. This has increased the total amount of rPP in our products to 60 percent, further reducing both Prevex’s and our customers’ CO₂ footprint”, says Senior Advisor Niclas Caldén.

Constant quality control

The new machine is the second extruder at the Nykarleby factory – the older one has been used to make outlet pipes for kitchen water traps for 10 years. However, because it does not have enough capacity to make bathroom pipes as well, they have been supplied to Prevex by another manufacturer.

“Since our supplier could not deliver us pipes that are made using recycled plastic, we needed to move their manufacturing to our own factory”, explains Tomas Qvist, Production Foreman at the Injection Moulding department.

“Like the older machine, this one is equipped with an online quality control unit that detects possible holes in the pipes. This constant quality control is what makes it possible for us to use recycled material”, he continues.

Both extruders also have an automatic packaging system that reduces manual labour and speeds up production. However, the new machine is able to produce a wider range of pipes thanks to its more modern technology.

Broader expertise in plastic parts

Being able to manufacture all water trap pipes at the Nykarleby factory has improved Prevex’s security of supply. Qvist also emphasises that since most plastic parts are made at Prevex using injection moulding, the new investment plays an important role in growing the company’s know-how.

“We now have the opportunity to broaden our expertise by learning even more about extrusion technology. This also helps us keep our know-how up to date.”